|

At Kawo Mould, we have an innovative engineering staff, which consist of

over 30 engineers and technicians.

We establish a unique structure called "technology and costing

team", by which a designated manager can coordinate the whole design

process. And the process is conducted by the representatives from each

department, among which are Product Designers, Manufacturing Engineers,

Quality Engineers, etc . And all of them work as a unit so as to get the "

Best Practices" for the customers, which is our service guideline.

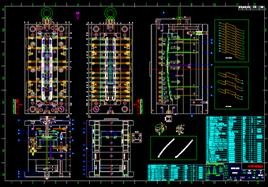

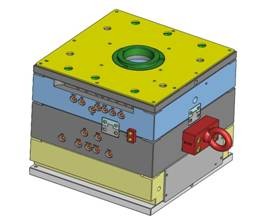

Kawo Mould has extensive CAD/CAM platforms and an Engineering

database transfer process to provide excellent flexibility to our customers.

Customer provides the 2D drawing or 3D data in DXF, DWG, PRT, SAT,

IGES, or STEP format. And we will appoint experienced engineers to design

the mould assembly drawing, and then customize project. By the way, we can

also scan samples submitted if necessary.

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM’s (Electro-Discharge Machining)

9. Wire-Cut Machines. |

|